Nunc a egestas lacus. Lorem ipsum dolor sit amet, consectetur zunc egestas lacus. Lorem ipsum dolor sit amet. London

© Copyright Qode Interactive 2018

Nunc a egestas lacus. Lorem ipsum dolor sit amet, consectetur zunc egestas lacus. Lorem ipsum dolor sit amet. London

© Copyright Qode Interactive 2018

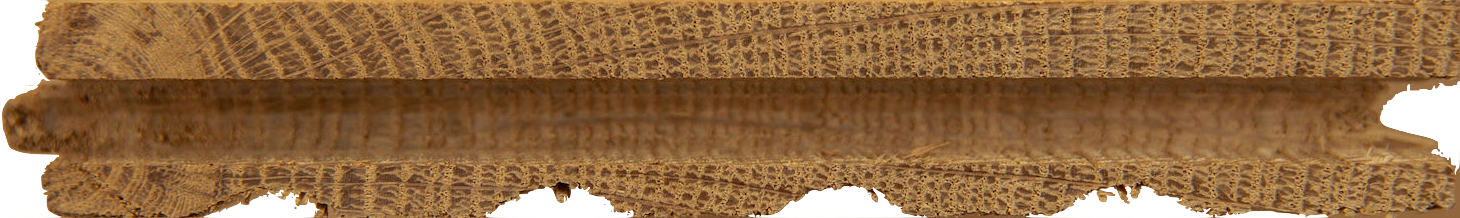

Rift and Quartered are terms that refer to the visual characteristics of the grading face of each board. The “ray fleck,” “flake,” or “figure” of a quarter-sawn board is the medullary ray of the log, which emanates outward from the center of the log like spokes of a wheel. The degree to which this “ray fleck” is revealed is a function of the angle of the growth rings to the face of the boards. When the growth rings are 90 degree to the face of the board the medullary ray is opened the greatest extent possible. As the angle of the growth rings to the face of the board decreases, less medullary ray fleck or (Quarter Sawn) is revealed. Rift boards and Quartered boards share one characteristic. The growth rings manifest themselves on the face of the board as straight grain, with no visible cathedral grain or plain sawn look.

Rift sawing is a technique of cutting boards from logs. Each board is cut along a radius of the original log, so that the saw cuts at right angles to the tree’s growth ring. This produces lumber of great stability.

Quarter-sawing gets its name from the fact that the log is first quartered lengthwise, resulting in wedges with a right angle ending at approximately the center of the original log. Each quarter is then cut separately by tipping it up on its point and sawing boards successively along the axis. That results in boards with the annual rings mostly perpendicular to the faces. Quarter sawing yields boards with straight striped grain lines, greater stability than flatsawn wood, and a distinctive ray and fleck figure. It also yields narrower boards, because the log is first quartered, and is more wasteful.

Quartersawn boards can also be produced by cutting a board from one flat face of the quarter, flipping the wedge onto the other flat face to cut the next board, and so on.

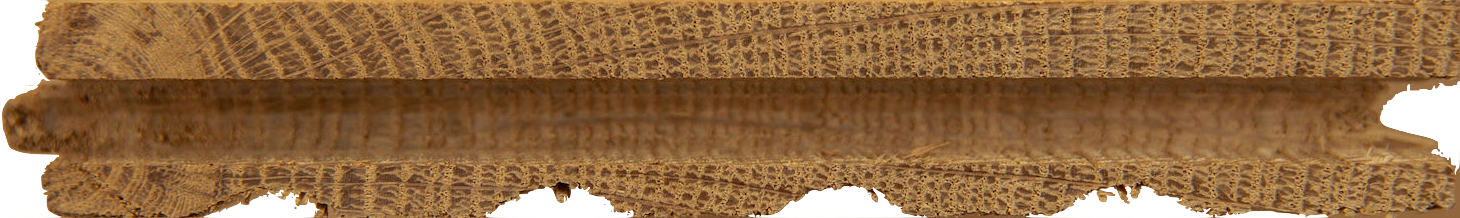

Rift and Quartered are terms that refer to the visual characteristics of the grading face of each board. The “ray fleck,” “flake,” or “figure” of a quarter-sawn board is the medullary ray of the log, which emanates outward from the center of the log like spokes of a wheel. The degree to which this “ray fleck” is revealed is a function of the angle of the growth rings to the face of the boards. When the growth rings are 90 degree to the face of the board the medullary ray is opened the greatest extent possible. As the angle of the growth rings to the face of the board decreases, less medullary ray fleck or (Quarter Sawn) is revealed. Rift boards and Quartered boards share one characteristic. The growth rings manifest themselves on the face of the board as straight grain, with no visible cathedral grain or plain sawn look.

Rift sawing is a technique of cutting boards from logs. Each board is cut along a radius of the original log, so that the saw cuts at right angles to the tree’s growth ring. This produces lumber of great stability.

Quarter-sawing gets its name from the fact that the log is first quartered lengthwise, resulting in wedges with a right angle ending at approximately the center of the original log. Each quarter is then cut separately by tipping it up on its point and sawing boards successively along the axis. That results in boards with the annual rings mostly perpendicular to the faces. Quarter sawing yields boards with straight striped grain lines, greater stability than flatsawn wood, and a distinctive ray and fleck figure. It also yields narrower boards, because the log is first quartered, and is more wasteful.

Quartersawn boards can also be produced by cutting a board from one flat face of the quarter, flipping the wedge onto the other flat face to cut the next board, and so on.

In plain sawing the log is passed through the blade cutting off plank after plank without changing the orientation of the blade or log. The resulting planks have different annual ring orientations when viewed from the end. The relative angle that form the rings and the surface go from almost zero degrees in the external planks to almost ninety degrees at log core.

Rift and Quartered are terms that refer to the visual characteristics of the grading face of each board. The “ray fleck,” “flake,” or “figure” of a quarter-sawn board is the medullary ray of the log, which emanates outward from the center of the log like spokes of a wheel. The degree to which this “ray fleck” is revealed is a function of the angle of the growth rings to the face of the boards. When the growth rings are 90 % to the face of the board the medullary ray is opened the greatest extent possible. As the angle of the growth rings to the face of the board decreases, less medullary ray fleck or (Quarter Sawn) is revealed. Rift boards and Quartered boards share one characteristic. The growth rings manifest themselves on the face of the board as straight grain, with no visible cathedral grain or plain sawn look.

Rift sawing is a technique of cutting boards from logs. Each board is cut along a radius of the original log, so that the saw cuts at right angles to the tree’s growth ring. This produces lumber of great stability.

Quarter-sawing gets its name from the fact that the log is first quartered lengthwise, resulting in wedges with a right angle ending at approximately the center of the original log. Each quarter is then cut separately by tipping it up on its point and sawing boards successively along the axis. That results in boards with the annual rings mostly perpendicular to the faces. Quarter sawing yields boards with straight striped grain lines, greater stability than flatsawn wood, and a distinctive ray and fleck figure. It also yields narrower boards, because the log is first quartered, and is more wasteful.

Quartersawn boards can also be produced by cutting a board from one flat face of the quarter, flipping the wedge onto the other flat face to cut the next board, and so on.